This page describes the management mode of the site with reference to the personal data processing of users consulting it.

This is information for those who interact with the web services of MECVEL S.r.l. company, available on www.mecvel.com.

The processing of personal data provided and or deduced browsing the site is undergone with these purposes:

- To allow the access and the browsing of the site (service execution)

- To process anonymous statistics on the use of the site (legitimate interest)

- To check the correct functioning status of the site and identify any responsibility in case of unlawful acts during the browsing (legitimate interest)

Informatics systems and software procedures used for the correct working of the site collect, during their functioning, some personal data whose transmission is included in the use of Internet communication protocols: accessing the site leads the company to get these data.

In general, we inform you that your personal data processing will be done with electronic devices and could consist of their collection, registration, storage, modification, communication, and cancellation. All personal data processed by MECVEL S.r.l. are protected by appropriate security measures, according to the current legislation and for the time strictly necessary to fulfil purposes (one year for site visitors).

Personal data collected in accordance with what is mentioned above will not be communicated or disclosed to third parts unless requested by judicial authorities.

According to the art. 13 of RGPD (EU) 2016/679, we remind you that you have the right to request to MECVEL S.r.l. access to your personal data, their correction, cancellation (where applicable) or limitation of processing.

It also has the right to revoke the authorization for data processing for which the consent has been given, as well as the right to submit a complaint to the Personal Data Protection Authority.

All the rights mentioned above can be exercised writing to info@mecvel.com.

We will reply you as soon as possible.

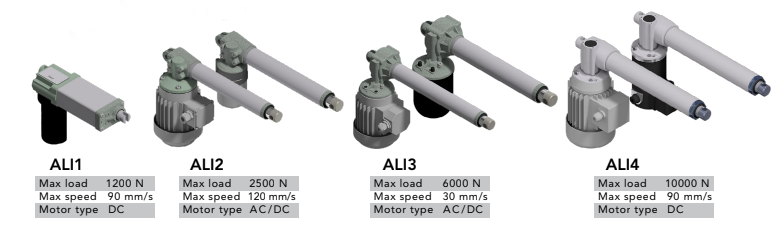

machines:

machines: