Our responses to a survey dedicated to the packaging industry have been taken up and published by one of the most authoritative Italian magazines in the automation sector.

Read the interview below and discover the solutions proposed by MecVel technologies in the field of linear motion.

The new challenges of the Packaging Industry

Q. Any sector must inevitably face new challenges continuously, given that all industrial contexts are certainly not static.

Are the Italian Packaging companies able to maintain the necessary pace of innovation, despite a country system that is not adequate, or is international competition starting to erode the leadership acquired over time?

More specifically, in your opinion, what are the main challenges for the Packaging sector today and in the near future?

A. In the packaging sector, as well as in many other industrial fields, the goal is to achieve greater automation and customization of the machine and of the related components to place itself in every market niche and satisfy the customer’s requirements in detail, which is constantly looking for high-performance, “plug-and-play” solutions tailored to its needs.

In packaging, the optimization of the work cycle to minimize downtime and increase production remains fundamental, as does the automation of the entire chain and the various stations along the production line, from the processing of the raw product to the finished product packaging.

Speed and flexibility are other essential elements for each machine to demonstrate that it can effectively and efficiently process products that are also different in shape, weight, and material.

Above all, the elimination of plastic in favour of recyclable and ecological packaging becomes important, as well as the implementation along the production lines of electrical systems to replace the hydraulic or pneumatic ones to make the sector increasingly green and eco-sustainable.

Packaging and technology

Q. In any industrial sector, among the technologies we are talking about and considered indispensable for growth and competitiveness, we should mention robotics, IIoT, artificial intelligence, Blockchain, and augmented reality.

And of course not only that.

Are these technologies, and others, entering the world of Packaging?

And what about the necessary skills to use them?

A. The most suitable and widespread new technologies in the packaging sector are primarily robotics, from arms to AGVs, and traceability.

While the first is necessary for the automation and versatility of production processes and the optimization of flows, the second is as important for the company as it is for the final consumer.

The constant monitoring along the production line and the possibility of tracing back at any time to the various processing phases crossed by the product, allow to exponential increase in the level of control and safety on the processes, reducing the margins of error considering that, moreover, the data traced must be carefully collected, stored and easily consulted.

Especially in robotics, another field in continuous evolution, there is an increasingly frequent meeting between mechanics and electronics, and this brings with it the need to have a series of skills that must range in both sectors, to combine them in the best possible way and draw from them an advantage in terms of innovation.

At the same time, the market requires technologies that are intuitive and easy to apply even by end users, so the right compromise must be sought.

Market proposals

Q. Which of your proposals do you think best meets the needs of the packaging machinery manufacturers sector?

Which solutions are to be considered most innovative, such as to distinguish you from your competitors?

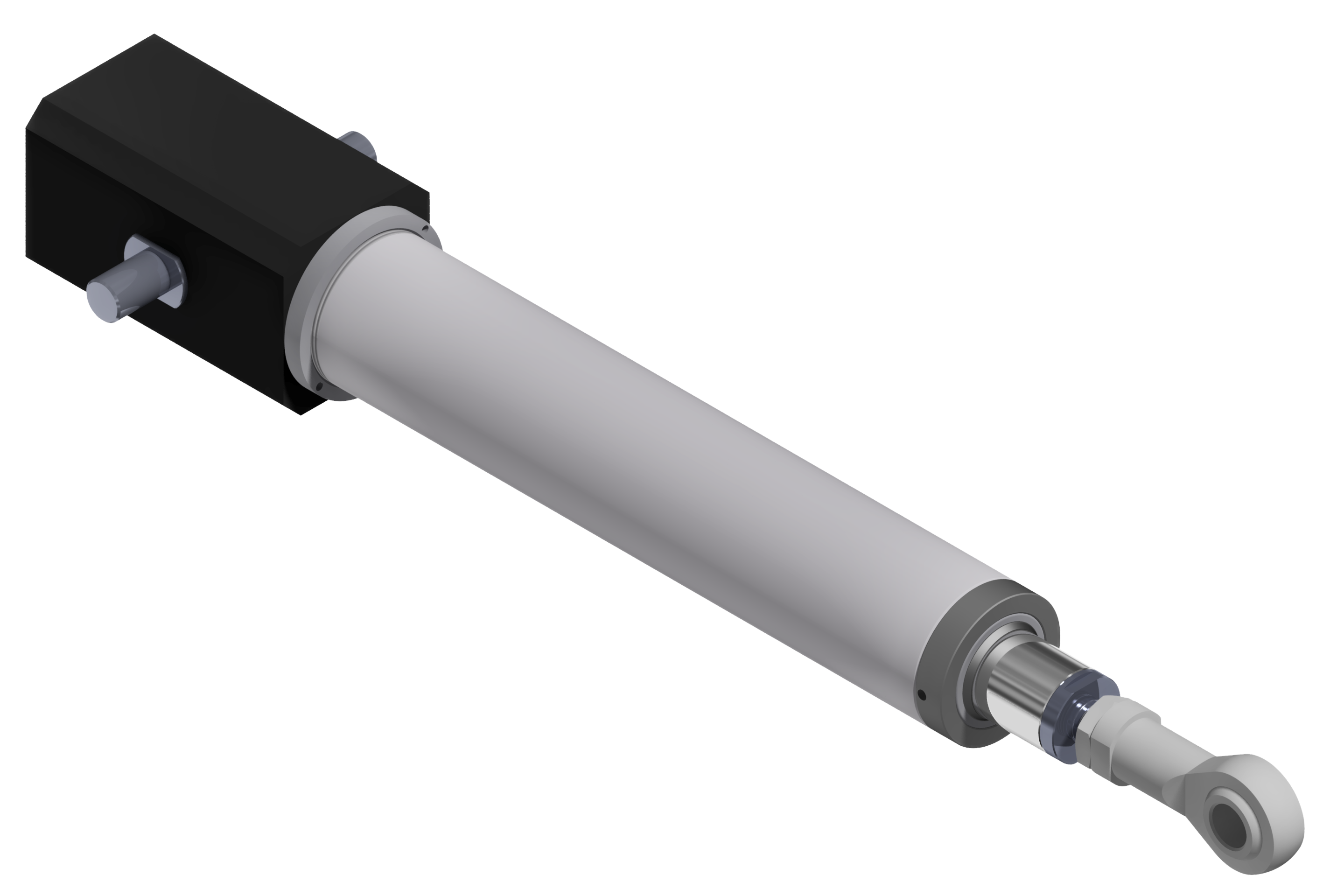

A. Our company, MecVel Srl, has more than thirty years of experience in the linear automation sector, and its core business is the design and production of electric linear actuators, devices which transform the rotary motion of a motor into a pull or push for loads up to 20 tons.

These also blend perfectly with the packaging sector to the extent that a high-performance, fast, versatile product is required that uses an electrical system, therefore eco-friendly and non-polluting.

Flexibility is given by the customization service provided by MecVel, aimed at configuring each electric linear actuator to adapt it to the technical specifications of the application for which it is intended.

For the packaging sector, we have a trump card to play with regard to linear automation along production lines.

Extruders and blow moulding or injection machines, format change and edge guiding, end of the line, AGV, for each of these stations MecVel has the customized product for the linear movement to be performed, from the height adjustment of the rollers to the control of the direction of the product on the conveyor belt, up to the management of the steering and the loading/unloading platform of the AGV.

The AM series is the most suitable for medium loads (15,000 N max.) without sacrificing speed, precision and complete control, as it offers the possibility of mounting even the latest generations of the servo, stepper and brushless motors, placing itself close to real servo-actuation and creating systems that are perfectly interchangeable with pneumatic cylinders.