Electric linear actuators: an “evergreen” product for a constantly growing market

Why analysing the electric linear actuators market and the forecast period, results show an increase of +9% and a value of more than 70 billion by 2028? Because these technologies, able to transform the rotatory motion of an electric motor into a linear movement, play a strategic role in the automation of industrial processes and systems, bringing a series of important benefits.

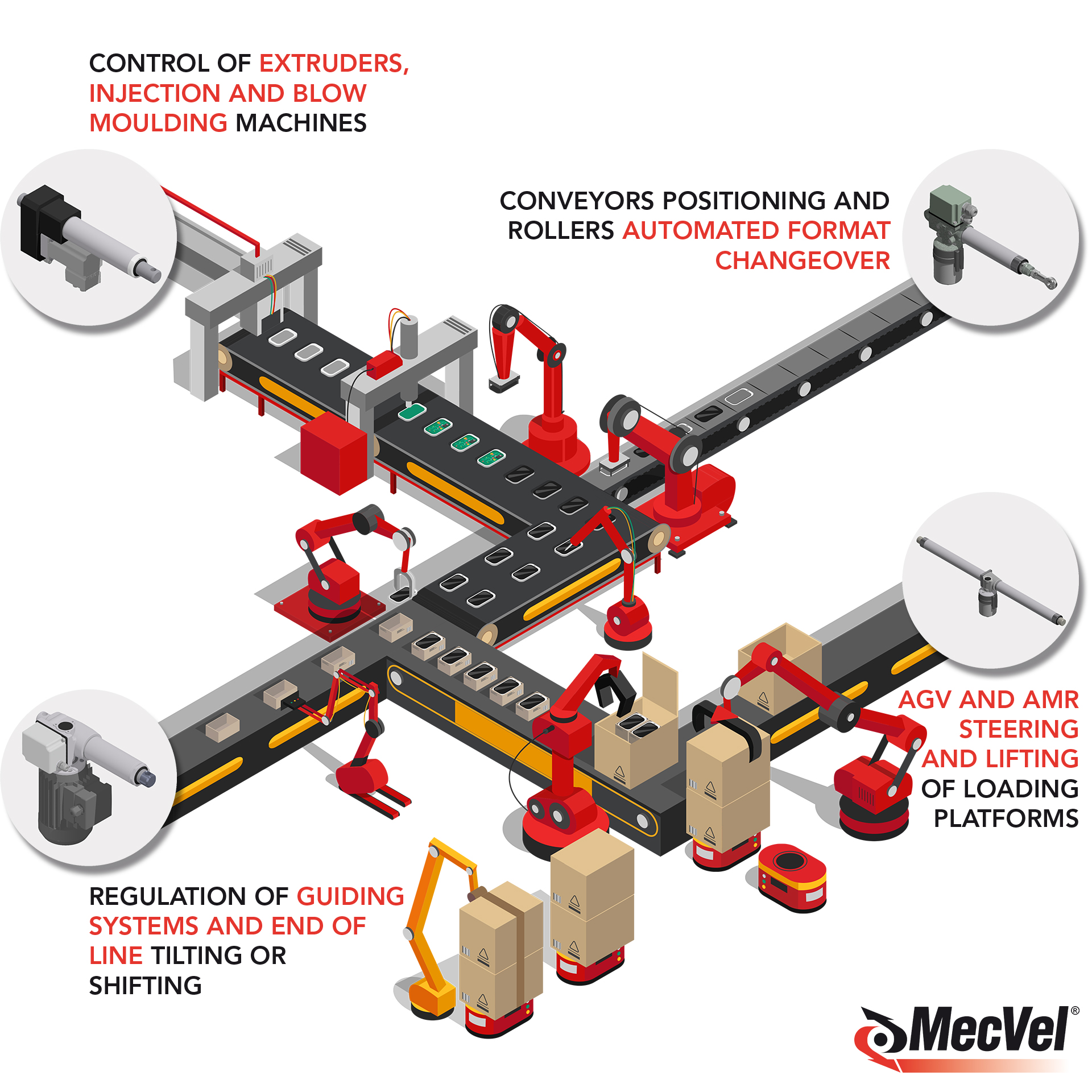

Electric linear actuators are “passe-partout” products, with transversal use in several fields. In addition, the MecVel customization service allows configuring them in order to perfectly meet the technical specifications of the industrial applications for which they are intended.

In fact, since 1987 MecVel is one of the main players in the automation field, thanks to an effective, versatile and “eco-friendly” range of electric linear actuators, with load capacity up to 20 tons and relatively high speed.

Electric linear actuators: a smart, steady technology

Specifically, these motion transmission devices are characterized mainly by these advantages:

• Electric system. It allows to regulate the power supplied and it is extremely compact, both in terms of overall dimensions (it avoids all the components required by hydraulic and pneumatic systems) and connections needed for its operation

• Optimal stroke control and positioning accuracy. Unlike hydraulic and pneumatic systems, electric linear actuators can be arrested in intermediate positions of the stroke, that can be controlled by different devices: limit switches, encoder, potentiometer allow to have a constant feedback on the position reached by the electric linear actuator, for a better handling of the motion

• Integration with electronics and high-efficiency motors as servo, brushless, stepper. While the first allows to set specific ramps and tailored movement routines, the second leads to a significant increase in performance, offering systems interchangeable with pneumatic cylinders and results close to servo-actuation, in particular in terms of speed and repeatability of the motion. Changing the kind of motorization, the product is perfectly suitable also for easier linear motions, reducing costs and entering the market with a competitive price-quality ratio

• Compatibility with PLC and remote control. The possibility to control the product “remotely” and to communicate effectively with a PLC makes the electric linear actuator suitable for industrial fields where all the machines are controlled by these systems

• Almost no maintenance, minimal wear and long life both for product and whole application, with extremely low consumption

Linear electric actuators and 4.0 industry principles

The more and more frequent choice of the electric linear actuator as solution is related also to the increase of automation and robotics in the industrial field, the need to adopt products able to ensure a continuous production and at the same time meet the linear motion requests of customers.

In fact, these devices allow to automate processes, making them more reliable, safe, fast, precise and error-free, optimizing the duty cycle, minimizing the downtime and increasing the efficiency of the system or the machine in which they are used.

Electric linear actuators and sustainability

To complete the picture, the current trends and the compliance with new regulations require to switch to solutions with low energy impact and without polluting agents,and this leads to the progressive replacement of hydraulic and pneumatic cylinders with electric linear actuators, able to provide higher performance in terms of flexibility and energy efficiency.

Moreover, the fact that electric linear actuators do not use oil to work, makes them suitable for applications in sterile environments (medical, pharmaceutical and food industries), as they are free from leaks that could cause dangerous contamination.

MecVel works constantly to innovate its proposal and its future is strongly oriented towards the new needs of linear motion and industrial automation, with the purpose to satisfy them through a “green” technology, able to meet the industry 4.0 concepts of sustainable production.

For more info contact us!