In every industrial field, there is constant research for new technologies allowing to get greater results, increasing performance and general efficiency.

Regarding linear handling requests, it’s becoming more and more recommended focus on the advantages of electric systems instead of hydraulic or pneumatic ones.

Replace hydraulic or pneumatic cylinders with electric linear actuators

The almost consolidated trend is to switch from hydraulic or pneumatic cylinders to electric linear actuators, with particular reference to some industrial fields such as packaging and automatic machines.

The main purpose is to have better control and greater versatility in automation, as well as deep customization of the machine or the system in which the electric linear actuator is mounted.

Advantages of the electric system compared to the hydraulic or pneumatic one

Electric linear actuators can replace hydraulic or pneumatic cylinders providing at the same time some advantages, differently from these other systems:

• They are more performing. They have great accuracy in positioning, can reach a high speed while maintaining constant control of the stroke and offer the possibility to stop or repeat the motion also in a very short time. They demonstrate flexibility, being suitable for a wide range of industrial fields, as they can work with high temperatures, dust and vibrations

• They are cheaper, both in terms of development and maintenance of the product. Design and production times for an electric linear actuator are faster and, once installed, require very little maintenance, allowing also for significant energy saving. The system is mostly “plug & play”, and composed of a few compact elements

• They are more ecological. These systems use electricity, which is a “green” energy. Pollution levels, in terms of environmental impact, heat and noise, are minimal. Moreover, as electric linear actuators do not use oil, they are suitable for working in sterile environments (medical, pharmaceutical, food), as free from leaks that can cause harmful contaminations

Electric linear actuators and environmental benefits

Today, particular attention must be given to the environment: MecVel products use an electric and eco-sustainable system and require minimal and controlled use of plastic.

In addition, they aren’t polluting, as no oil is needed to operate, and have not components such as compressors, pumps, valves, or pipes, avoiding a bigger environmental impact. Moreover, electric linear actuators cannot undergo variations in pressure or flow, increasing the quality of the motion performed.

Advantages for the packaging industry

Advantages are very relevant in the packaging industry. The implementation of electric systems on production lines (replacing hydraulic or pneumatic ones) has shown an increase in productivity, optimizing the processes, with almost zero downtime, and making this field eco-friendly without any loss in terms of efficiency.

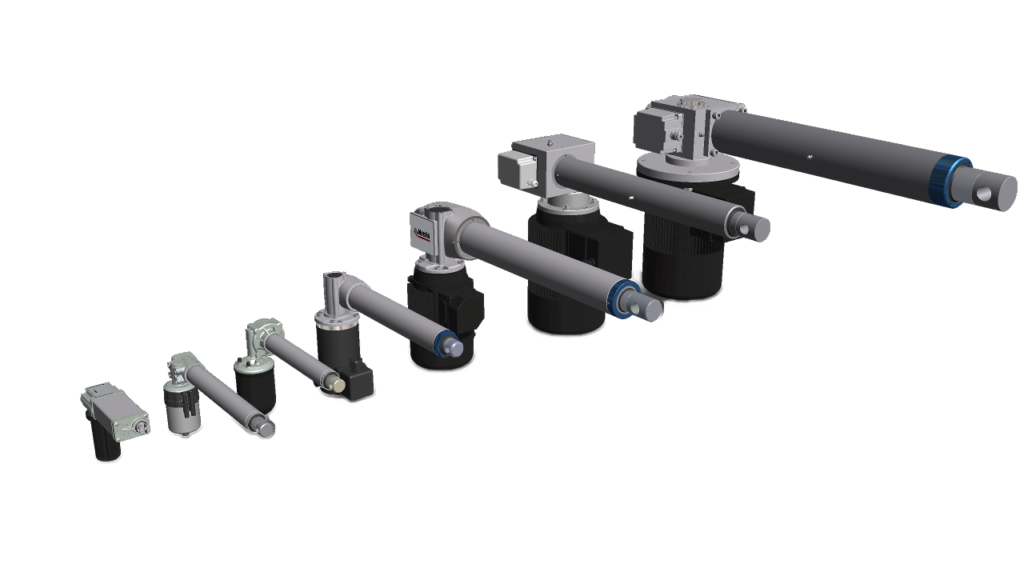

In detail, MecVel offers the following solutions:

• Automated format changeover: regulation of the rollers position according to the product processed or the kind of packaging

• Guiding systems: adjustment of the material direction on the conveyor belt during diverting and packaging phases

• End of line solutions: loading/unloading of baskets with finished or raw material

3 specific answers to the new industry challenges

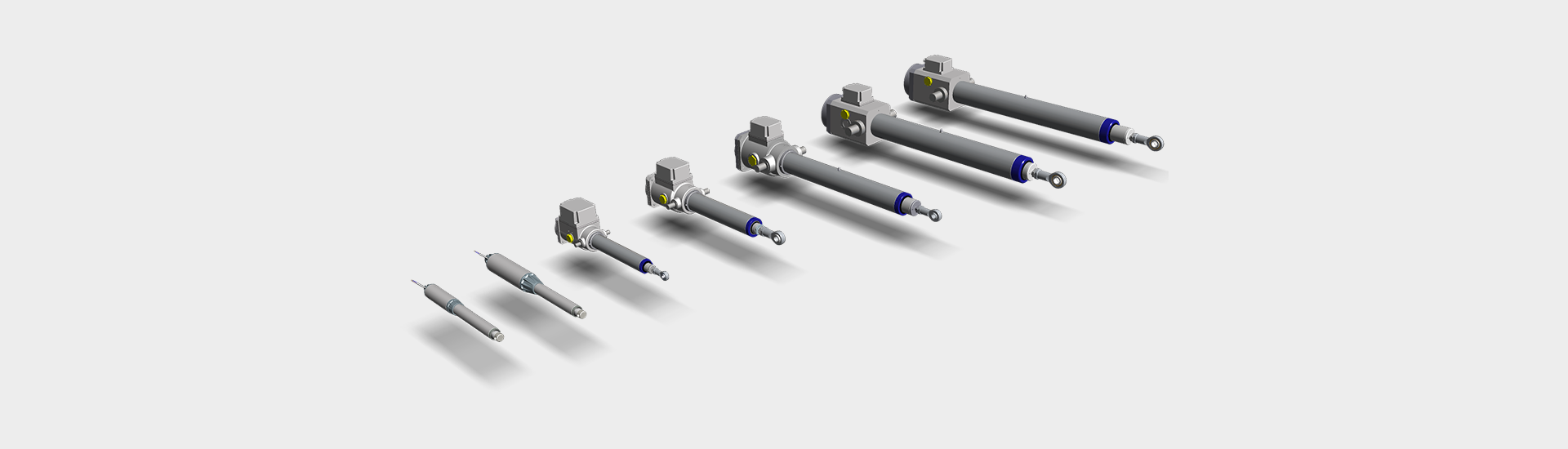

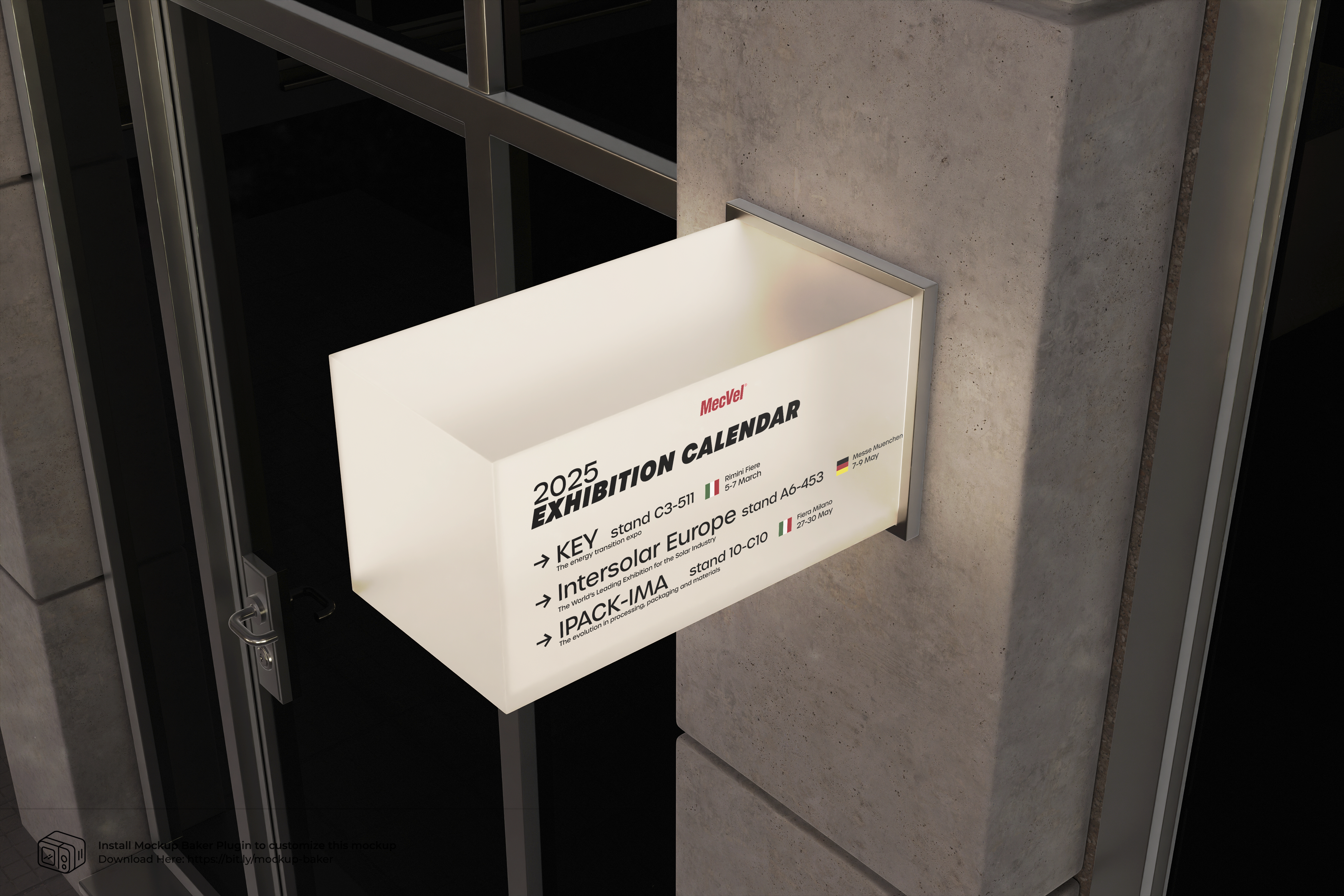

1. Advanced technologies. Since 1987, MecVel is in the linear automation field, developing and manufacturing a wide range of electric linear actuators constantly updated according to market requests: a valid response in alternative to hydraulic or pneumatic systems

2. Experience and innovation. The deep technical know-how allows the company to constantly work on technologically advanced linear motion proposals, which can combine efficiency, reliability and safety, anticipating customer demands

3. Customized design. MecVel offers an important customization service. This tool allows the customer to configure each product according to the technical specifications of the application to which it is intended, providing tailored solutions

For more information, contact us.