Electric linear actuators are electromechanical components needed in linear automation processes in many industrial areas. Let’s find out in detail what they are, and the application fields of these devices.

What is an electric linear actuator?

By definition, it is a system creating and performing a motion, through a set of mechanisms able to transform a certain kind of energy into a new shape.

In particular, electricity becomes a linear movement.

Electric linear actuators convert the rotatory motion of a motor into a pulling or pushing movement, applying a force on a single axis.

They are widely used in the handling of different kinds of load and can be suitable for several industrial applications.

Which are the main application fields for electric linear actuators?

These products are used almost wherever it is possible to automate linear movements.

For example, without these devices, there wouldn’t be the automatic adjustment of conveyor belts, diverters, and mobile robots used in the production lines of heavy industry rather than packaging, automotive, logistics and zootechnics ones.

Electric linear actuators are also used in the renewable energy field.

For example, they are involved in the opening and closing of dams, the orientation of photovoltaic panels and solar concentrators, the control of wind turbines, rather than radar in the civil branch, as well as in the inclination of snow-making systems and dust suppression guns.

They are also suitable for different means of transport, acting as a switching system or for the opening and closing of doors in rope-hauled transportation systems, in railways and the naval industry.

The linear handling can be performed by an electric linear actuator also in the medical field: from physiotherapy or dental chairs to X-ray equipment and diagnostic machinery, up to surgery tables with automatic movement.

How do these mechanisms work?

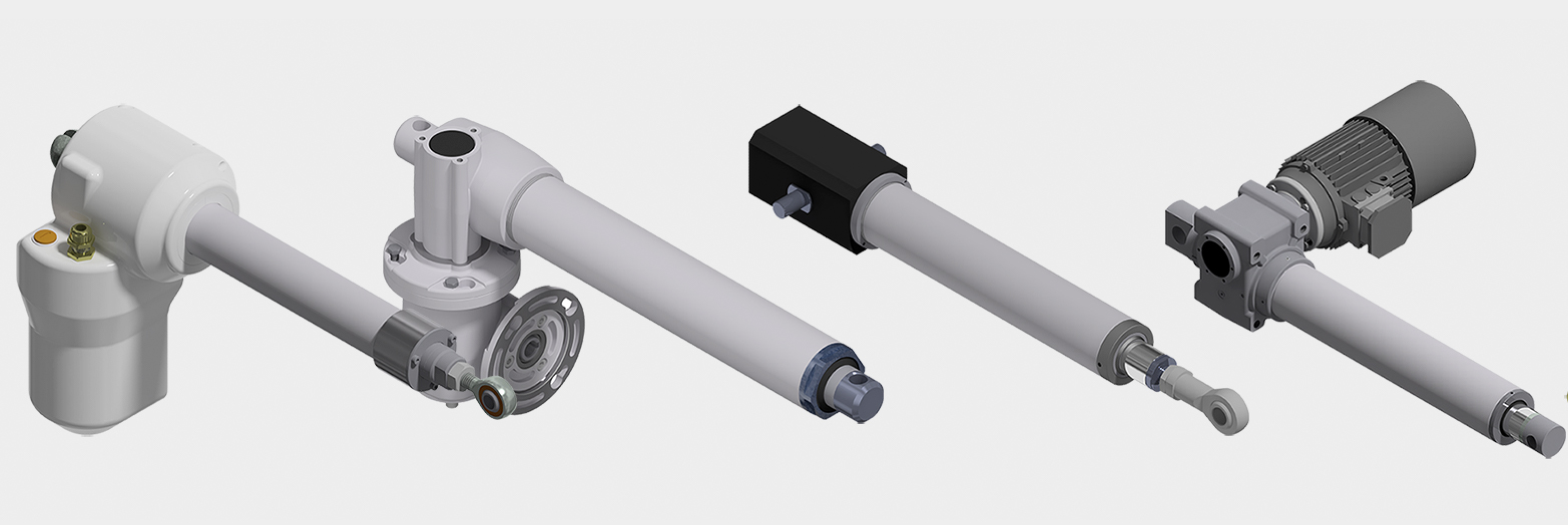

The transformation of the rotatory motion of the electric motor into a linear movement can be realized with various internal mechanism sets.

Each one has its own features, and for this reason each MecVel electric linear actuator is manufactured with different sets, according to the application field.

In general, the main features for selecting an electric linear actuator are:

• Force: weight to be handled, in N. The weight to be moved is called a dynamic load, while the weight to be kept is called static load

• Speed: time required to complete the stroke, in mm/s

• Stroke: linear excursion to be performed, in mm

• Control: limit switches, potentiometer, encoder allow constant and precise feedback on the movement

• Power supply: DC (12 or 24 V) or AC (single-phase or three-phase) motor

• Gear box: worm or planetary gear

• Screw: TPN (trapezoidal) or VRS (ball screw)

• Duty cycle: alternation of work and rest phases of the electric linear actuator

The duty cycle required by the application is given by the ratio between the working time under load in the stated period, and the stated period itself (5 minutes), expressed in percentage:

• With Fs ≤ 30%, a TPN is recommended

• With Fs ≥ 30% a VRS is recommended

Which are the advantages of electric linear actuators?

Surely, the versatility: these components allow to push, pull, lift, orient, and position loads up to 20 tons in an automated way, optimizing, and making easier and more efficient those processes that would require time and energy.

The choice of the electric system for MecVel is not casual: in this way, the company offers maximum eco-sustainability and performance in terms of motion transmission, with controlled use of plastics and, if compared to hydraulic or pneumatic systems, electric linear actuators provide the possibility to stop the stroke in intermediate positions, have a clean and easy installation, while the absence of valves, tubes and compressors avoid maintenance and risks of contamination.

For more information, please contact us: we can supply tailored solutions for any industrial field, thanks to our R&D team that, through a customization service, designs each product according to the technical specification of the application to which it is intended.

Ask for more details here.